I have recently taken up 3D printing as a hobby. As a coder and creator, it only seemed natural. This page serves as public notes and links relating to getting my printer up and running. I have a FlashForge Creator Pro and have been using it primarily for architectural modeling (nothing beats a 3D printed 8th scale darth vader).

Troubleshooting

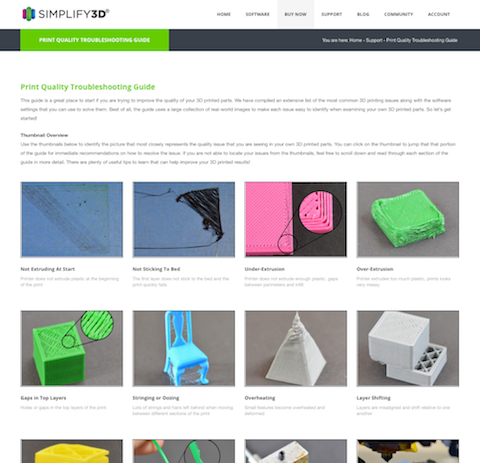

3D printing was no easy feat right off the bat. So many variables to consider, all dependant on the conditions, model you are printing, filament, etc...I've been using a couple of programs but regardless, the best resource I have found is Simplify3D's troubleshooting guide. Check it out, it's epic.

I also use the settings prescribed by the official and unofficial setup/user manuals. They call for the standard 120°C heated bed, 230°C extruder, and a feedrate around 3000 mm/min. I'm finding that the included ABS filament is wanting to run less, round 215-220° (any lower and the layers don't stick well enough and higher won't adhere to the bed), and that the heated bed for large prints is nice at first but warping happens after a 5-10 layers. This sucks because you have a ice cream sandwich, warm-cool-warm which doesn't make for happy prints or customers. I'll post more here as I play with things but a resource I was using helped...

Slicers / Software

The models can come from anywhere (Rhino/Revit/SketchUp/etc) but the slicers I like the best are ReplicatorG and Simplify3D. ReplicatorG does a solid job at what it can, but is limited when you start to get adventurous. It has consistently given good results (it's slow but the implementation of the Sailfish firmware with accelerated printing is nice) when only printing with one color at a variety of model sizes. I also use the costly Simplify3D package which is so stinkin' fast with slicing it's hard to go back to RepG. It overwhelms you with features which is nice and terrible at the same time. I use it for the dual extrusions because it gives a nice preview of the models. It also removes the need to customize your gcode for turning on/off the blower at certain layers when printing PLA (I turn it on after layer 2 so that I know my first layer sticks to the blue tape), among other quirks. It also prints a skirt/brim, which I link for silly reasons. One of those things I suppose.Settings

I'll go into bullet mode because it makes more sense that way.Hatchbox PLA

- Bed: Unheated, covered in blue tape

- Filament: 195°C Extruders

- Feed rate: 3600mm/min (with retraction of 1mm for ooze control)

- Blower: 0% on layers 1-2, 100% everything else

FlashForge ABS

- Bed: 100°C, covered in fresh blue tape (I'll reuse tape for small prints)

- Filament: 220°C Extruders

- Feed rate: 3600mm/min (with retraction of 1mm for ooze control)

- Blower: 0% on layers 1-5, 8% everything else (I'm not convinced this helps but I'm seeing less warping on large prints...)

Need something printed?

I'm printing things for people in Ames, 3D Hubs has proven to work pretty well. I've processed a few orders here so feel free to throw me a challenge...

Order a 3D Print via 3d Hubs

Recent Projects